In this tutorial we will learn how to use the MPU6050 Accelerometer and Gyroscope sensor with the Arduino. First, I will explain how the MPU6050 works and how to read the data from it, and then we will make two practical examples.

Overview

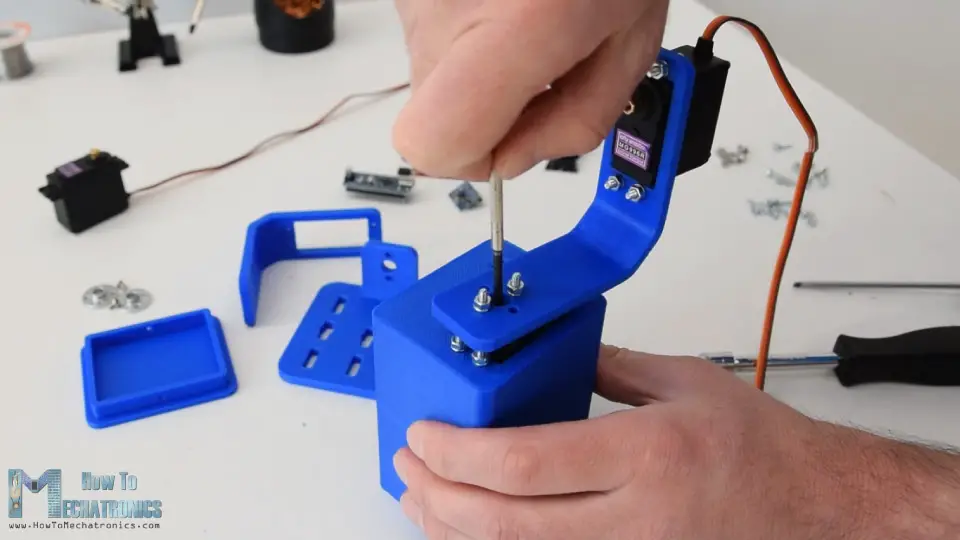

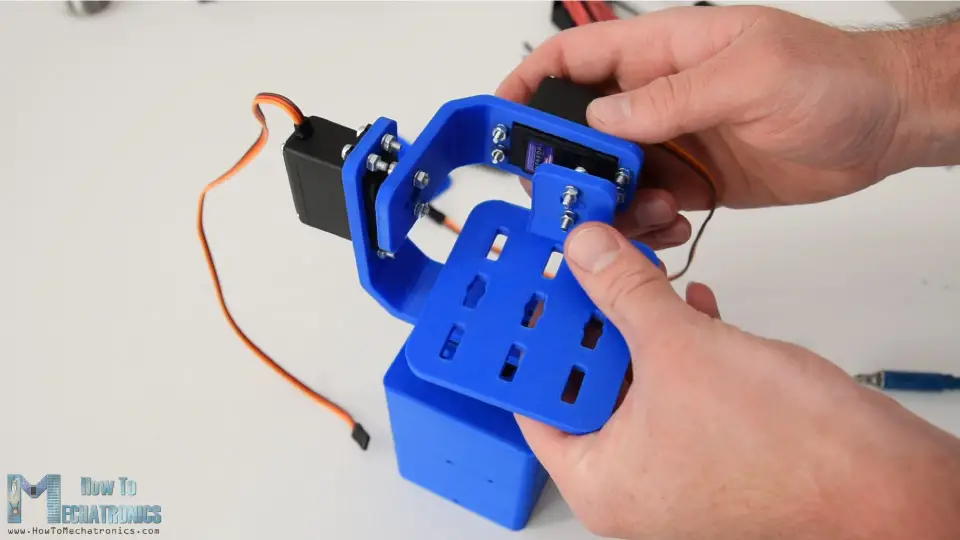

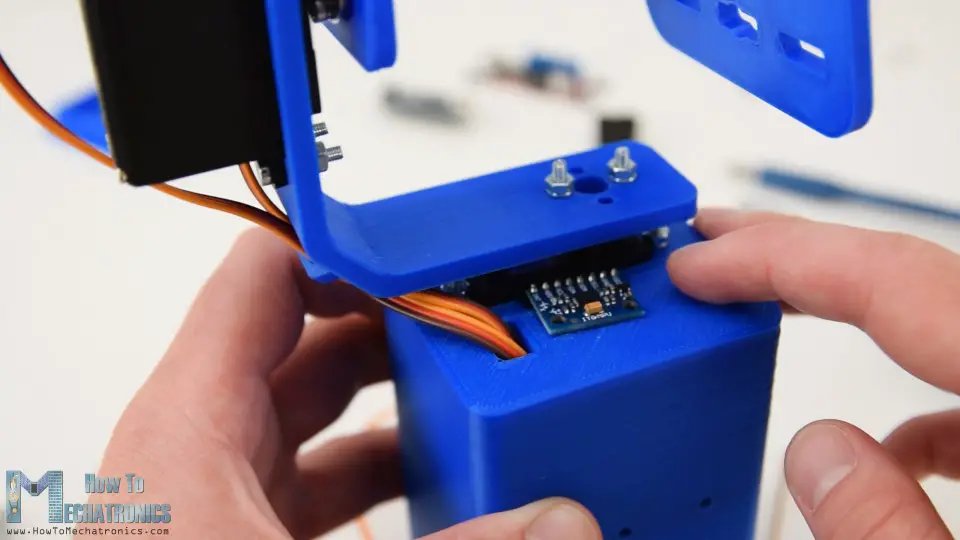

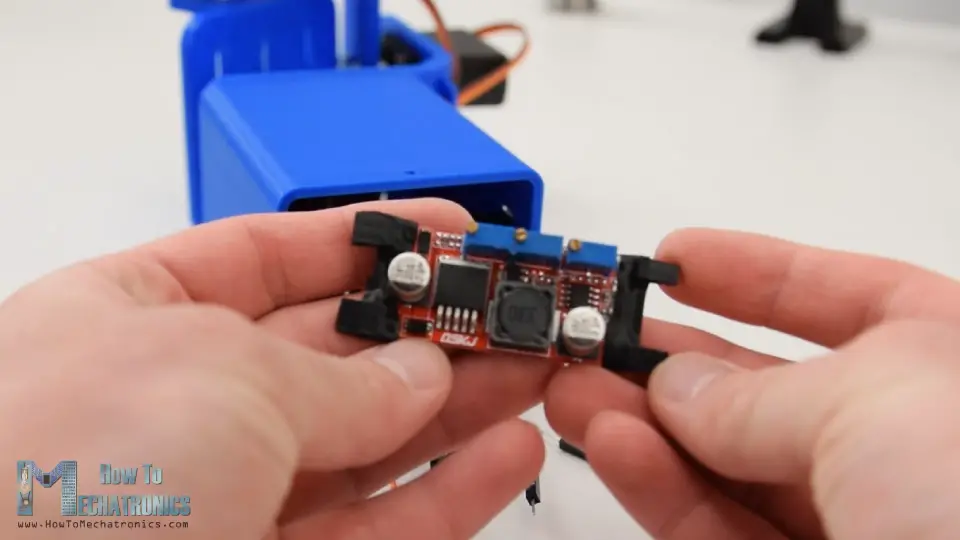

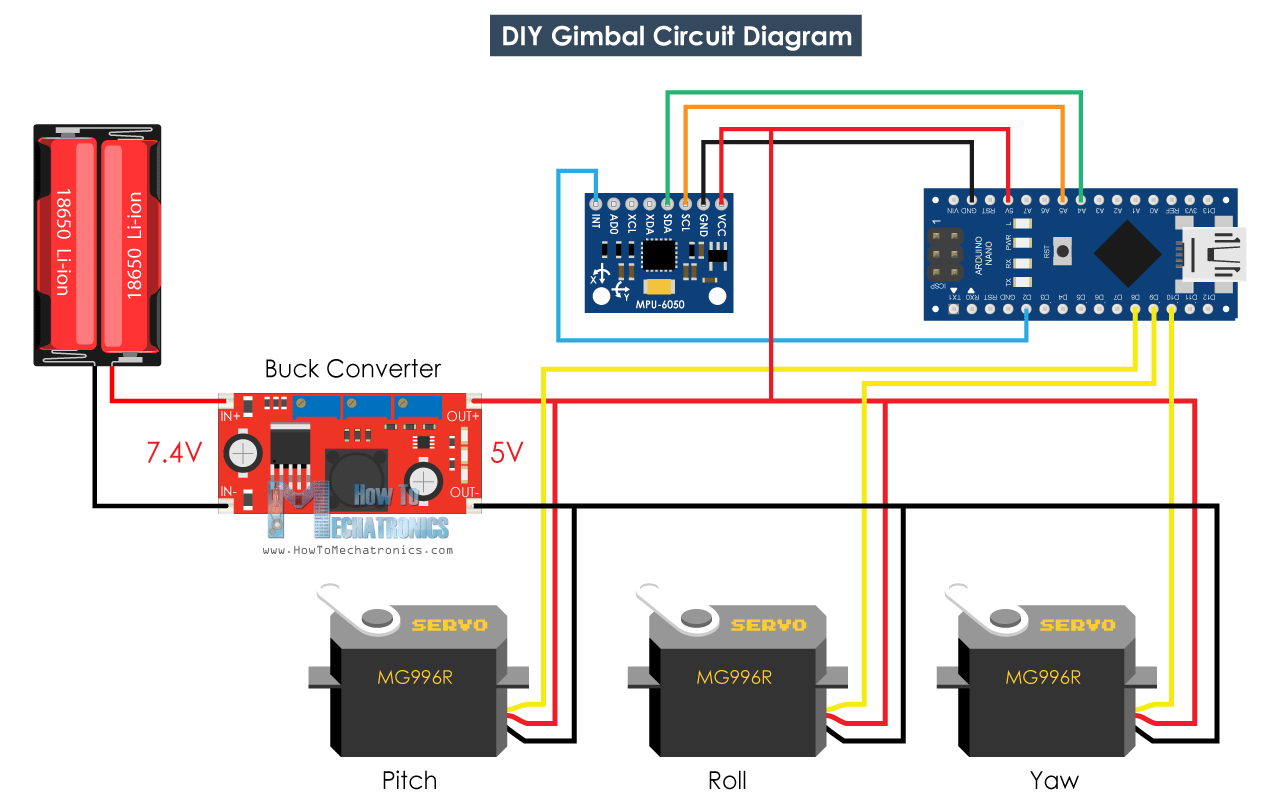

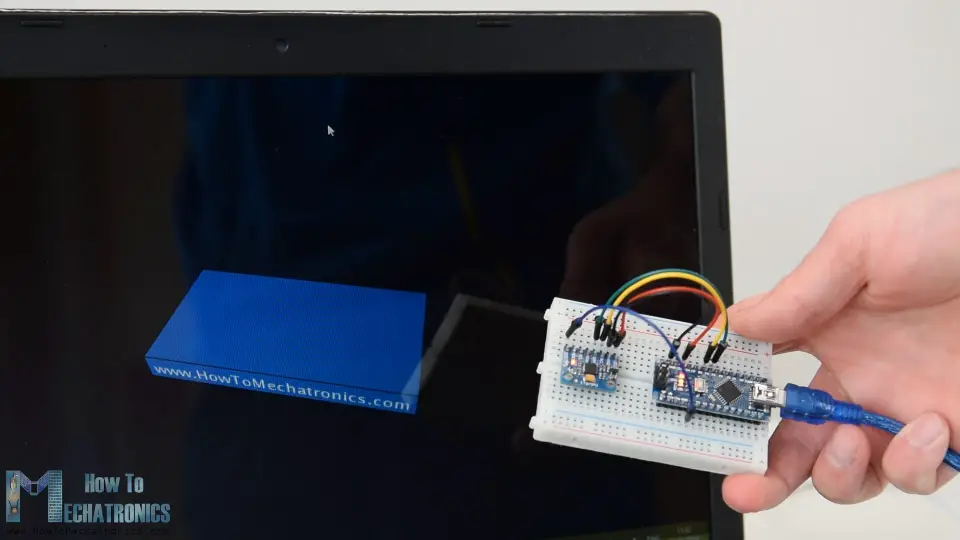

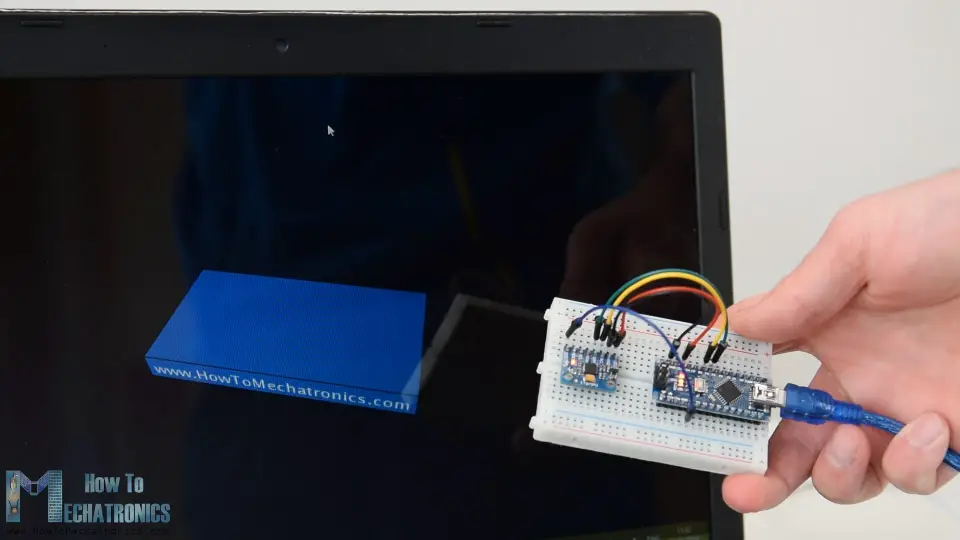

In the first example, using the Processing development environment, we will make a 3D visualization of the sensor orientation, and in the second example we will make a simple self-stabilizing platform or a DIY Gimbal. Based on the MPU6050 orientation and its fused accelerometer and gyroscope data, we control the three servos that keep the platform level.

How It Works

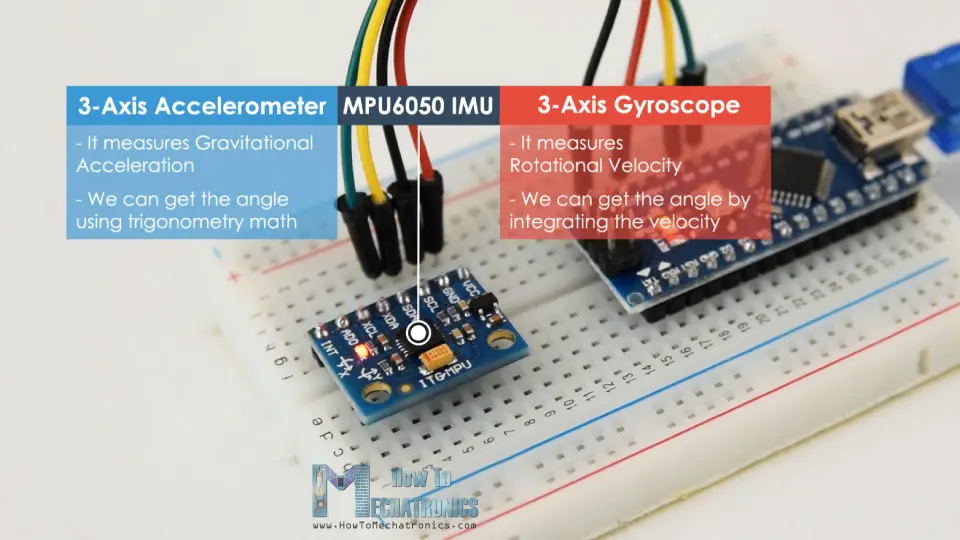

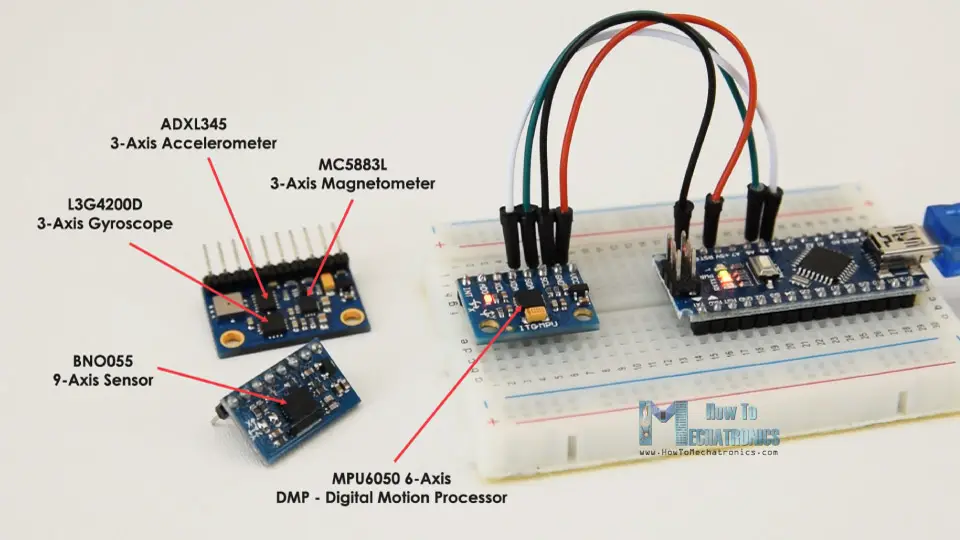

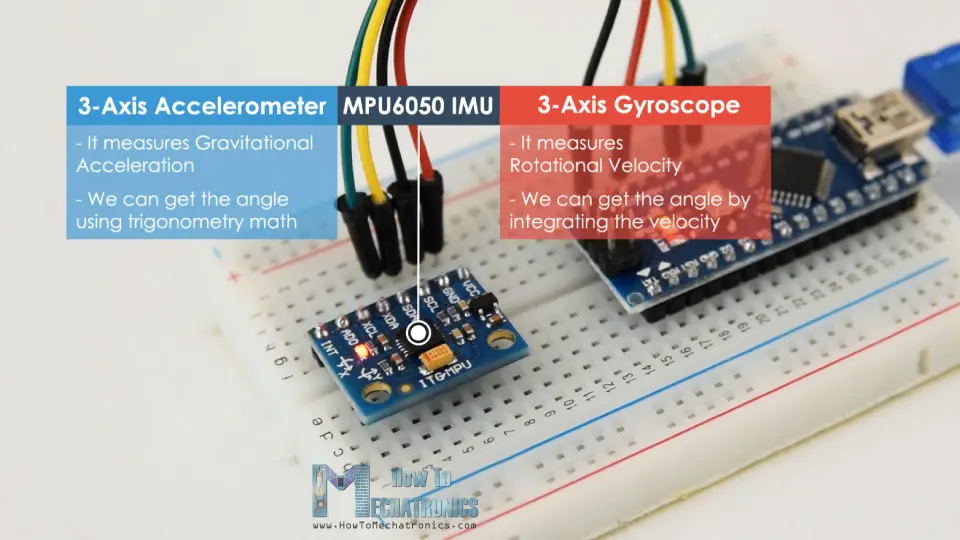

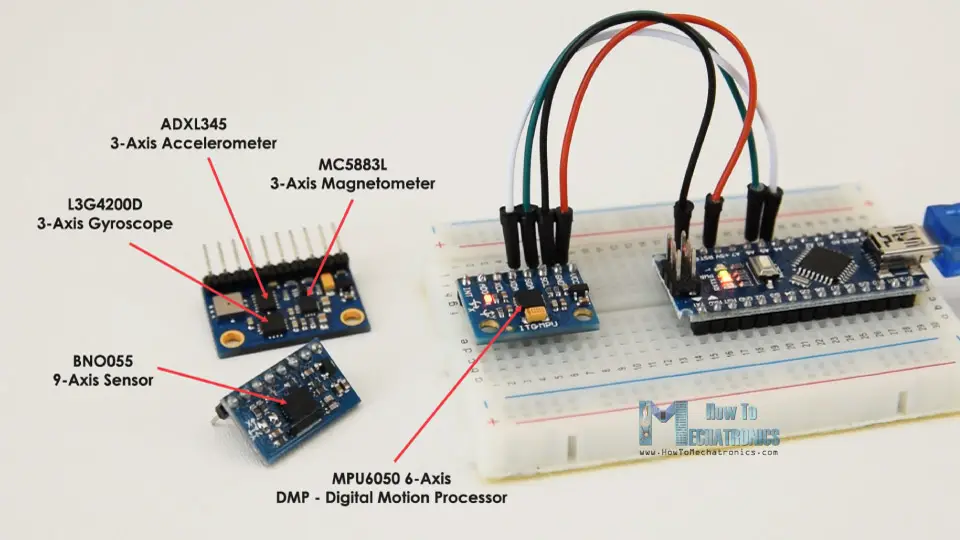

The MPU6050 IMU has both 3-Axis accelerometer and 3-Axis gyroscope integrated on a single chip.

The gyroscope measures rotational velocity or rate of change of the angular position over time, along the X, Y and Z axis. It uses MEMS technology and the Coriolis Effect for measuring, but for more details on it you can check my particular How MEMS Sensors Work tutorial. The outputs of the gyroscope are in degrees per second, so in order to get the angular position we just need to integrate the angular velocity.

On the other hand, the MPU6050 accelerometer measures acceleration in the same way as explained in the previous video for the ADXL345 accelerometer sensor. Briefly, it can measure gravitational acceleration along the 3 axes and using some trigonometry math we can calculate the angle at which the sensor is positioned. So, if we fuse, or combine the accelerometer and gyroscope data we can get very accurate information about the sensor orientation.

The MPU6050 IMU is also called six-axis motion tracking device or 6 DoF (six Degrees of Freedom) device, because of its 6 outputs, or the 3 accelerometer outputs and the 3 gyroscope outputs.

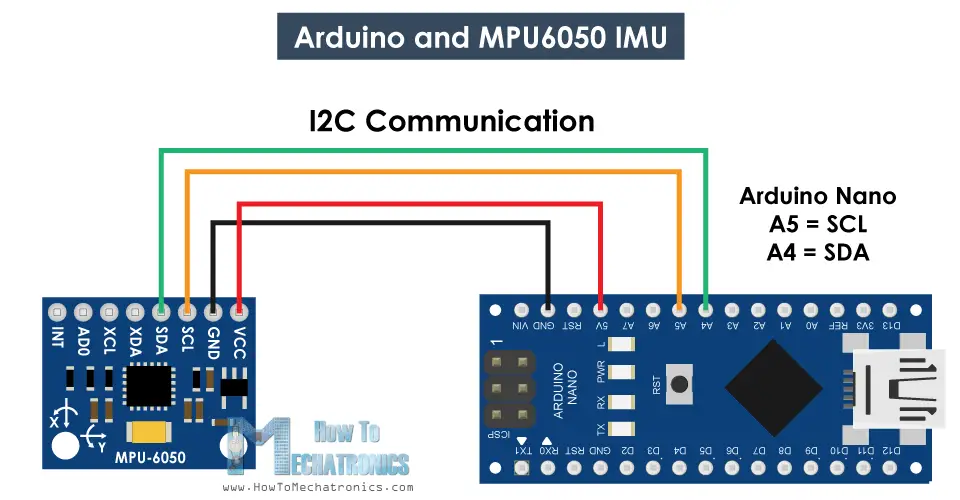

Arduino and MPU6050

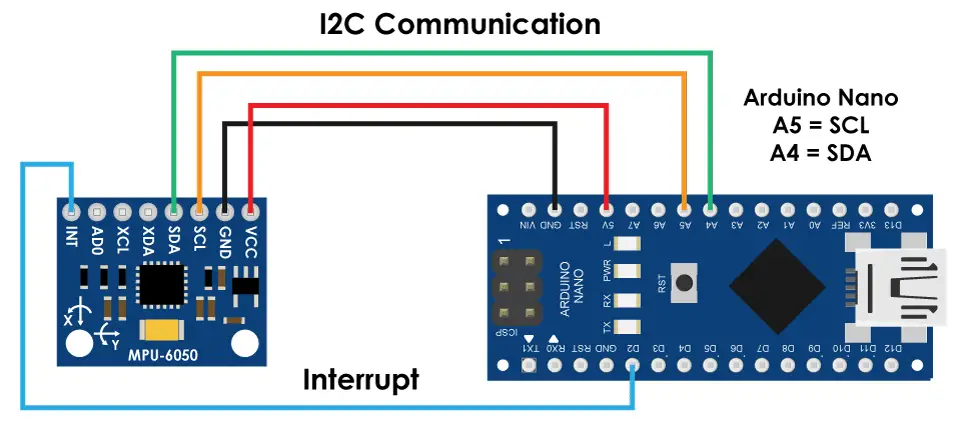

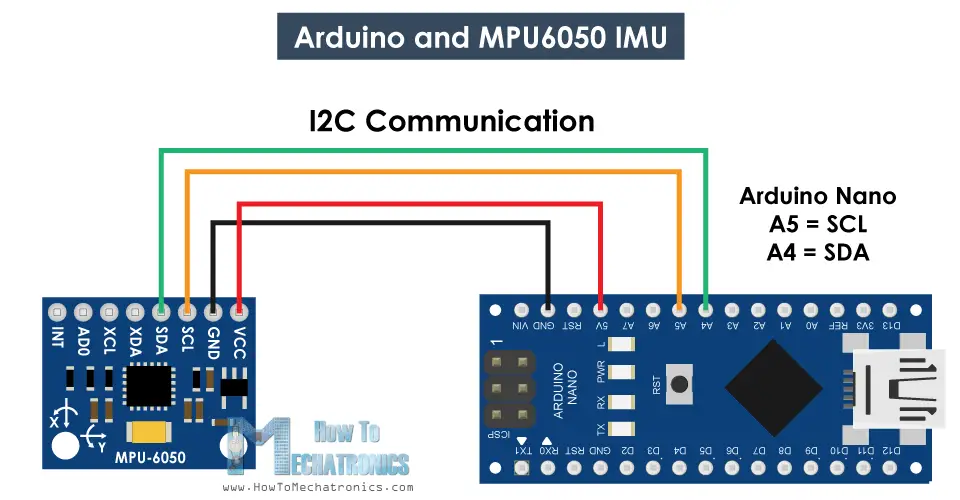

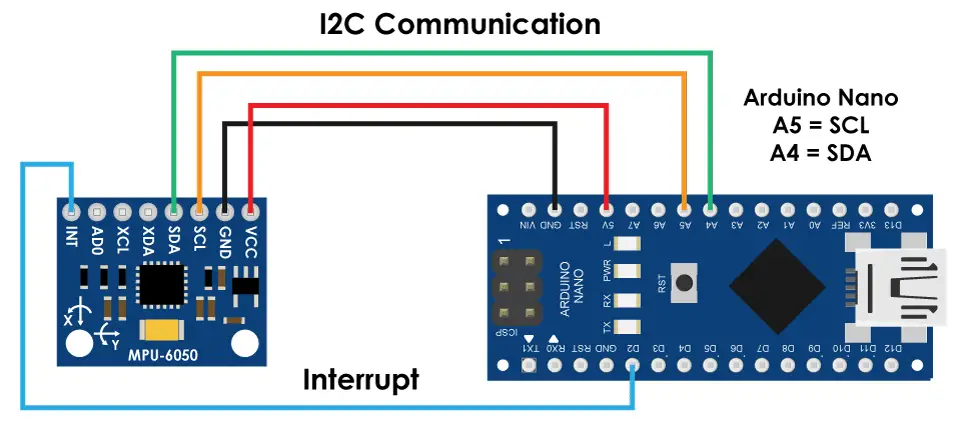

Let’s take a look how we can connect and read the data from the MPU6050 sensor using the Arduino. We are using the I2C protocol for communication with the Arduino so we need only two wires for connecting it, plus the two wires for powering.

You can get the components needed for this Arduino Tutorial from the links below:

*Please note: These are affiliate links. I may make a commission if you buy the components through these links. I would appreciate your support in this way!

MPU6050 Arduino Code

Here’s the Arduino code for reading the data from the MPU6050 sensor. Below the code you can find a detail description of it.

/*

Arduino and MPU6050 Accelerometer and Gyroscope Sensor Tutorial

by Dejan, https://howtomechatronics.com

*/

#include <Wire.h>

const int MPU = 0x68; // MPU6050 I2C address

float AccX, AccY, AccZ;

float GyroX, GyroY, GyroZ;

float accAngleX, accAngleY, gyroAngleX, gyroAngleY, gyroAngleZ;

float roll, pitch, yaw;

float AccErrorX, AccErrorY, GyroErrorX, GyroErrorY, GyroErrorZ;

float elapsedTime, currentTime, previousTime;

int c = 0;

void setup() {

Serial.begin(19200);

Wire.begin(); // Initialize comunication

Wire.beginTransmission(MPU); // Start communication with MPU6050 // MPU=0x68

Wire.write(0x6B); // Talk to the register 6B

Wire.write(0x00); // Make reset - place a 0 into the 6B register

Wire.endTransmission(true); //end the transmission

/*

// Configure Accelerometer Sensitivity - Full Scale Range (default +/- 2g)

Wire.beginTransmission(MPU);

Wire.write(0x1C); //Talk to the ACCEL_CONFIG register (1C hex)

Wire.write(0x10); //Set the register bits as 00010000 (+/- 8g full scale range)

Wire.endTransmission(true);

// Configure Gyro Sensitivity - Full Scale Range (default +/- 250deg/s)

Wire.beginTransmission(MPU);

Wire.write(0x1B); // Talk to the GYRO_CONFIG register (1B hex)

Wire.write(0x10); // Set the register bits as 00010000 (1000deg/s full scale)

Wire.endTransmission(true);

delay(20);

*/

// Call this function if you need to get the IMU error values for your module

calculate_IMU_error();

delay(20);

}

void loop() {

// === Read acceleromter data === //

Wire.beginTransmission(MPU);

Wire.write(0x3B); // Start with register 0x3B (ACCEL_XOUT_H)

Wire.endTransmission(false);

Wire.requestFrom(MPU, 6, true); // Read 6 registers total, each axis value is stored in 2 registers

//For a range of +-2g, we need to divide the raw values by 16384, according to the datasheet

AccX = (Wire.read() << 8 | Wire.read()) / 16384.0; // X-axis value

AccY = (Wire.read() << 8 | Wire.read()) / 16384.0; // Y-axis value

AccZ = (Wire.read() << 8 | Wire.read()) / 16384.0; // Z-axis value

// Calculating Roll and Pitch from the accelerometer data

accAngleX = (atan(AccY / sqrt(pow(AccX, 2) + pow(AccZ, 2))) * 180 / PI) - 0.58; // AccErrorX ~(0.58) See the calculate_IMU_error()custom function for more details

accAngleY = (atan(-1 * AccX / sqrt(pow(AccY, 2) + pow(AccZ, 2))) * 180 / PI) + 1.58; // AccErrorY ~(-1.58)

// === Read gyroscope data === //

previousTime = currentTime; // Previous time is stored before the actual time read

currentTime = millis(); // Current time actual time read

elapsedTime = (currentTime - previousTime) / 1000; // Divide by 1000 to get seconds

Wire.beginTransmission(MPU);

Wire.write(0x43); // Gyro data first register address 0x43

Wire.endTransmission(false);

Wire.requestFrom(MPU, 6, true); // Read 4 registers total, each axis value is stored in 2 registers

GyroX = (Wire.read() << 8 | Wire.read()) / 131.0; // For a 250deg/s range we have to divide first the raw value by 131.0, according to the datasheet

GyroY = (Wire.read() << 8 | Wire.read()) / 131.0;

GyroZ = (Wire.read() << 8 | Wire.read()) / 131.0;

// Correct the outputs with the calculated error values

GyroX = GyroX + 0.56; // GyroErrorX ~(-0.56)

GyroY = GyroY - 2; // GyroErrorY ~(2)

GyroZ = GyroZ + 0.79; // GyroErrorZ ~ (-0.8)

// Currently the raw values are in degrees per seconds, deg/s, so we need to multiply by sendonds (s) to get the angle in degrees

gyroAngleX = gyroAngleX + GyroX * elapsedTime; // deg/s * s = deg

gyroAngleY = gyroAngleY + GyroY * elapsedTime;

yaw = yaw + GyroZ * elapsedTime;

// Complementary filter - combine acceleromter and gyro angle values

roll = 0.96 * gyroAngleX + 0.04 * accAngleX;

pitch = 0.96 * gyroAngleY + 0.04 * accAngleY;

// Print the values on the serial monitor

Serial.print(roll);

Serial.print("/");

Serial.print(pitch);

Serial.print("/");

Serial.println(yaw);

}

void calculate_IMU_error() {

// We can call this funtion in the setup section to calculate the accelerometer and gyro data error. From here we will get the error values used in the above equations printed on the Serial Monitor.

// Note that we should place the IMU flat in order to get the proper values, so that we then can the correct values

// Read accelerometer values 200 times

while (c < 200) {

Wire.beginTransmission(MPU);

Wire.write(0x3B);

Wire.endTransmission(false);

Wire.requestFrom(MPU, 6, true);

AccX = (Wire.read() << 8 | Wire.read()) / 16384.0 ;

AccY = (Wire.read() << 8 | Wire.read()) / 16384.0 ;

AccZ = (Wire.read() << 8 | Wire.read()) / 16384.0 ;

// Sum all readings

AccErrorX = AccErrorX + ((atan((AccY) / sqrt(pow((AccX), 2) + pow((AccZ), 2))) * 180 / PI));

AccErrorY = AccErrorY + ((atan(-1 * (AccX) / sqrt(pow((AccY), 2) + pow((AccZ), 2))) * 180 / PI));

c++;

}

//Divide the sum by 200 to get the error value

AccErrorX = AccErrorX / 200;

AccErrorY = AccErrorY / 200;

c = 0;

// Read gyro values 200 times

while (c < 200) {

Wire.beginTransmission(MPU);

Wire.write(0x43);

Wire.endTransmission(false);

Wire.requestFrom(MPU, 6, true);

GyroX = Wire.read() << 8 | Wire.read();

GyroY = Wire.read() << 8 | Wire.read();

GyroZ = Wire.read() << 8 | Wire.read();

// Sum all readings

GyroErrorX = GyroErrorX + (GyroX / 131.0);

GyroErrorY = GyroErrorY + (GyroY / 131.0);

GyroErrorZ = GyroErrorZ + (GyroZ / 131.0);

c++;

}

//Divide the sum by 200 to get the error value

GyroErrorX = GyroErrorX / 200;

GyroErrorY = GyroErrorY / 200;

GyroErrorZ = GyroErrorZ / 200;

// Print the error values on the Serial Monitor

Serial.print("AccErrorX: ");

Serial.println(AccErrorX);

Serial.print("AccErrorY: ");

Serial.println(AccErrorY);

Serial.print("GyroErrorX: ");

Serial.println(GyroErrorX);

Serial.print("GyroErrorY: ");

Serial.println(GyroErrorY);

Serial.print("GyroErrorZ: ");

Serial.println(GyroErrorZ);

}

Code Description: So first we need to include the Wire.h library which is used for the I2C communication and define some variables needed storing the data.

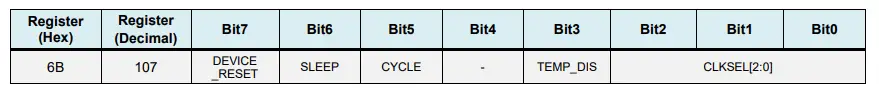

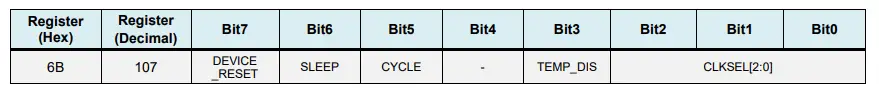

In the setup section, we need initialize the wire library and reset the sensor through the power management register. In order to do that we need to take a look at the datasheet of the sensor from where we can see the register address.

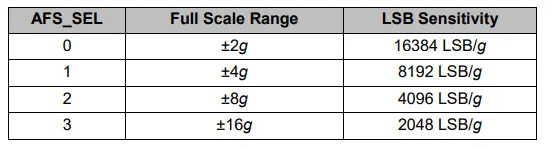

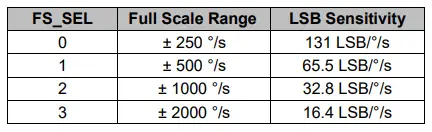

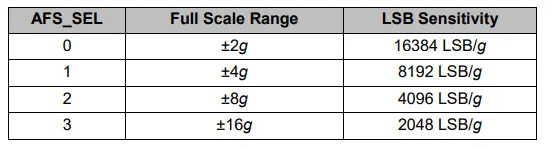

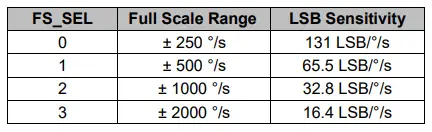

Also, if we want, we can select the Full-Scale Range for the accelerometer and the gyroscope using their configuration registers. For this example, we will use the default +- 2g range for the accelerometer and 250 degrees/s range for the gyroscope, so I will leave this part of the code commented.

// Configure Accelerometer Sensitivity - Full Scale Range (default +/- 2g)

Wire.beginTransmission(MPU);

Wire.write(0x1C); //Talk to the ACCEL_CONFIG register (1C hex)

Wire.write(0x10); //Set the register bits as 00010000 (+/- 8g full scale range)

Wire.endTransmission(true);

// Configure Gyro Sensitivity - Full Scale Range (default +/- 250deg/s)

Wire.beginTransmission(MPU);

Wire.write(0x1B); // Talk to the GYRO_CONFIG register (1B hex)

Wire.write(0x10); // Set the register bits as 00010000 (1000deg/s full scale)

Wire.endTransmission(true);

*/

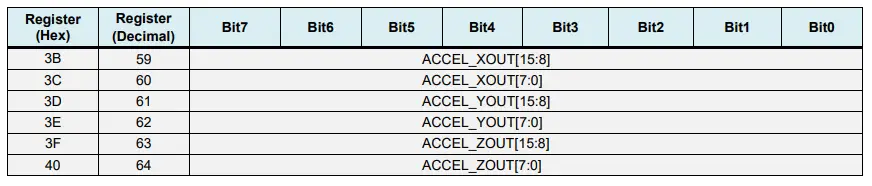

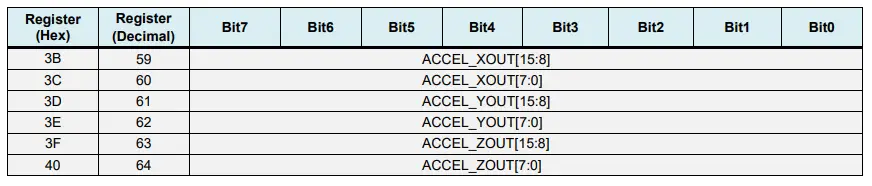

In the loop section we start by reading the accelerometer data. The data for each axis is stored in two bytes or registers and we can see the addresses of these registers from the datasheet of the sensor.

In order to read them all, we start with the first register, and using the requiestFrom() function we request to read all 6 registers for the X, Y and Z axes. Then we read the data from each register, and because the outputs are twos complement, we combine them appropriately to get the correct values.

// === Read acceleromter data === //

Wire.beginTransmission(MPU);

Wire.write(0x3B); // Start with register 0x3B (ACCEL_XOUT_H)

Wire.endTransmission(false);

Wire.requestFrom(MPU, 6, true); // Read 6 registers total, each axis value is stored in 2 registers

//For a range of +-2g, we need to divide the raw values by 16384, according to the datasheet

AccX = (Wire.read() << 8 | Wire.read()) / 16384.0; // X-axis value

AccY = (Wire.read() << 8 | Wire.read()) / 16384.0; // Y-axis value

AccZ = (Wire.read() << 8 | Wire.read()) / 16384.0; // Z-axis value

In order to get output values from -1g to +1g, suitable for calculating the angles, we divide the output with the previously selected sensitivity.

Finally, using these two formulas, we calculate the roll and pitch angles from the accelerometer data.

// Calculating Roll and Pitch from the accelerometer data

accAngleX = (atan(AccY / sqrt(pow(AccX, 2) + pow(AccZ, 2))) * 180 / PI) - 0.58; // AccErrorX ~(0.58) See the calculate_IMU_error()custom function for more details

accAngleY = (atan(-1 * AccX / sqrt(pow(AccY, 2) + pow(AccZ, 2))) * 180 / PI) + 1.58; // AccErrorY ~(-1.58)

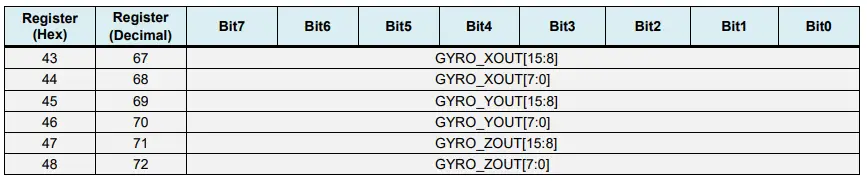

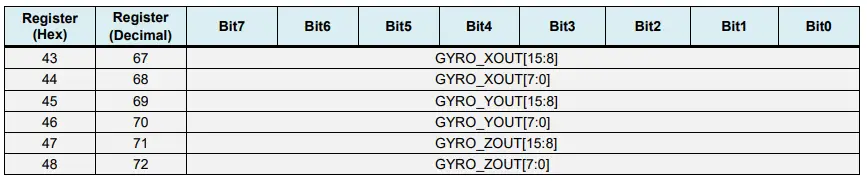

Next, using the same method we get the gyroscope data.

We read the six gyroscope registers, combine their data appropriately and divide it by the previously selected sensitivity in order to get the output in degrees per second.

// === Read gyroscope data === //

previousTime = currentTime; // Previous time is stored before the actual time read

currentTime = millis(); // Current time actual time read

elapsedTime = (currentTime - previousTime) / 1000; // Divide by 1000 to get seconds

Wire.beginTransmission(MPU);

Wire.write(0x43); // Gyro data first register address 0x43

Wire.endTransmission(false);

Wire.requestFrom(MPU, 6, true); // Read 4 registers total, each axis value is stored in 2 registers

GyroX = (Wire.read() << 8 | Wire.read()) / 131.0; // For a 250deg/s range we have to divide first the raw value by 131.0, according to the datasheet

GyroY = (Wire.read() << 8 | Wire.read()) / 131.0;

GyroZ = (Wire.read() << 8 | Wire.read()) / 131.0;

Here you can notice that I correct the output values with some small calculated error values, which I will explain how we get them in a minute. So as the outputs are in degrees per second, now we need to multiply them with the time to get just degrees. The time value is captured before each reading iteration using the millis() function.

// Correct the outputs with the calculated error values

GyroX = GyroX + 0.56; // GyroErrorX ~(-0.56)

GyroY = GyroY - 2; // GyroErrorY ~(2)

GyroZ = GyroZ + 0.79; // GyroErrorZ ~ (-0.8)

// Currently the raw values are in degrees per seconds, deg/s, so we need to multiply by sendonds (s) to get the angle in degrees

gyroAngleX = gyroAngleX + GyroX * elapsedTime; // deg/s * s = deg

gyroAngleY = gyroAngleY + GyroY * elapsedTime;

yaw = yaw + GyroZ * elapsedTime;

Finally, we fuse the accelerometer and the gyroscope data using a complementary filter. Here, we take 96% of the gyroscope data because it is very accurate and doesn’t suffer from external forces. The down side of the gyroscope is that it drifts, or it introduces error in the output as the time goes on. Therefore, on the long term, we use the data from the accelerometer, 4% in this case, enough to eliminate the gyroscope drift error.

// Complementary filter - combine acceleromter and gyro angle values

roll = 0.96 * gyroAngleX + 0.04 * accAngleX;

pitch = 0.96 * gyroAngleY + 0.04 * accAngleY;

However, as we cannot calculate the Yaw from the accelerometer data, we cannot implement the complementary filter on it.

Before we take a look at the results, let me quickly explain how to get the error correction values. For calculate these errors we can call the calculate_IMU_error() custom function while the sensor is in flat still position. Here we do 200 readings for all outputs, we sum them and divide them by 200. As we are holding the sensor in flat still position, the expected output values should be 0. So, with this calculation we can get the average error the sensor makes.

void calculate_IMU_error() {

// We can call this funtion in the setup section to calculate the accelerometer and gyro data error. From here we will get the error values used in the above equations printed on the Serial Monitor.

// Note that we should place the IMU flat in order to get the proper values, so that we then can the correct values

// Read accelerometer values 200 times

while (c < 200) {

Wire.beginTransmission(MPU);

Wire.write(0x3B);

Wire.endTransmission(false);

Wire.requestFrom(MPU, 6, true);

AccX = (Wire.read() << 8 | Wire.read()) / 16384.0 ;

AccY = (Wire.read() << 8 | Wire.read()) / 16384.0 ;

AccZ = (Wire.read() << 8 | Wire.read()) / 16384.0 ;

// Sum all readings

AccErrorX = AccErrorX + ((atan((AccY) / sqrt(pow((AccX), 2) + pow((AccZ), 2))) * 180 / PI));

AccErrorY = AccErrorY + ((atan(-1 * (AccX) / sqrt(pow((AccY), 2) + pow((AccZ), 2))) * 180 / PI));

c++;

}

//Divide the sum by 200 to get the error value

AccErrorX = AccErrorX / 200;

AccErrorY = AccErrorY / 200;

c = 0;

// Read gyro values 200 times

while (c < 200) {

Wire.beginTransmission(MPU);

Wire.write(0x43);

Wire.endTransmission(false);

Wire.requestFrom(MPU, 6, true);

GyroX = Wire.read() << 8 | Wire.read();

GyroY = Wire.read() << 8 | Wire.read();

GyroZ = Wire.read() << 8 | Wire.read();

// Sum all readings

GyroErrorX = GyroErrorX + (GyroX / 131.0);

GyroErrorY = GyroErrorY + (GyroY / 131.0);

GyroErrorZ = GyroErrorZ + (GyroZ / 131.0);

c++;

}

//Divide the sum by 200 to get the error value

GyroErrorX = GyroErrorX / 200;

GyroErrorY = GyroErrorY / 200;

GyroErrorZ = GyroErrorZ / 200;

// Print the error values on the Serial Monitor

Serial.print("AccErrorX: ");

Serial.println(AccErrorX);

Serial.print("AccErrorY: ");

Serial.println(AccErrorY);

Serial.print("GyroErrorX: ");

Serial.println(GyroErrorX);

Serial.print("GyroErrorY: ");

Serial.println(GyroErrorY);

Serial.print("GyroErrorZ: ");

Serial.println(GyroErrorZ);

}

We simply print the values on the serial monitor and once we know them, we can implement them in the code as shown earlier, for both the roll and pitch calculation, as well as for the 3 gyroscope outputs.

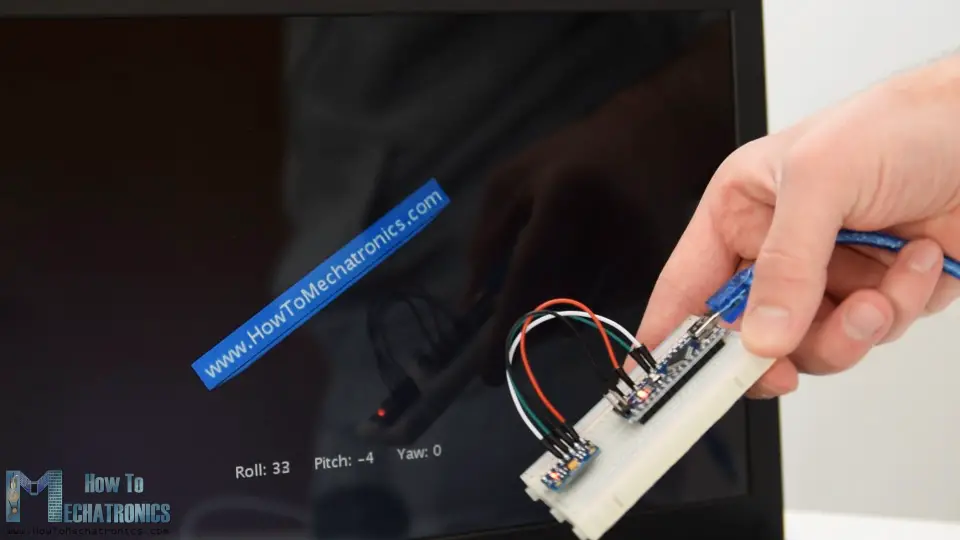

Finally, using the Serial.print function we can print the Roll, Pitch and Yaw values on the serial monitor and see whether the sensor works properly.

MPU6050 Orientation Tracking – 3D Visualization

Next, in order to make the 3D visualization example we just need accept this data the Arduino is sending through the serial port in the Processing development environment. Here’s the complete Processing code:

/*

Arduino and MPU6050 IMU - 3D Visualization Example

by Dejan, https://howtomechatronics.com

*/

import processing.serial.*;

import java.awt.event.KeyEvent;

import java.io.IOException;

Serial myPort;

String data="";

float roll, pitch,yaw;

void setup() {

size (2560, 1440, P3D);

myPort = new Serial(this, "COM7", 19200); // starts the serial communication

myPort.bufferUntil('\n');

}

void draw() {

translate(width/2, height/2, 0);

background(233);

textSize(22);

text("Roll: " + int(roll) + " Pitch: " + int(pitch), -100, 265);

// Rotate the object

rotateX(radians(-pitch));

rotateZ(radians(roll));

rotateY(radians(yaw));

// 3D 0bject

textSize(30);

fill(0, 76, 153);

box (386, 40, 200); // Draw box

textSize(25);

fill(255, 255, 255);

text("www.HowToMechatronics.com", -183, 10, 101);

//delay(10);

//println("ypr:\t" + angleX + "\t" + angleY); // Print the values to check whether we are getting proper values

}

// Read data from the Serial Port

void serialEvent (Serial myPort) {

// reads the data from the Serial Port up to the character '.' and puts it into the String variable "data".

data = myPort.readStringUntil('\n');

// if you got any bytes other than the linefeed:

if (data != null) {

data = trim(data);

// split the string at "/"

String items[] = split(data, '/');

if (items.length > 1) {

//--- Roll,Pitch in degrees

roll = float(items[0]);

pitch = float(items[1]);

yaw = float(items[2]);

}

}

}

Here we read the incoming data from the Arduino and put it into the appropriate Roll, Pitch and Yaw variables. In the main draw loop, we use these values to rotate the 3D object, in this case that’s a simple box with a particular color and text on it.

If we run the sketch, we can see how good the MPU6050 sensor is for tracking orientation. The 3D object tracks the orientation of the sensor quite accurate and it’s also very responsive.

As I mentioned, the only down side is that the Yaw will drift over time because we cannot use the complementary filter for it. For improving this we need to use an additional sensor. That’s usually a magnetometer which can be used as a long-term correction for the gyroscope Yaw drift. However, the MPU6050 actually have a feature that’s called Digital Motion Processor which is used for onboard calculations of the data and it’s capable of eliminating the Yaw drift.

Here’s the same 3D example with the Digital Motion Processor in use. We can see how accurate the orientation tracking is now, without the Yaw drift. The onboard processor can also calculate and output Quaternions which are used for representing orientations and rotations of objects in three dimensions. In this example we are actually using quaternions for representing the orientation which also doesn’t suffer from Gimbal lock which occurs when using Euler angles.

Nevertheless, getting this data from the sensor is a bit more complicated than what we explained earlier. First of all, we need to connect and additional wire to an Arduino digital pin. That’s an interrupt pin which is used for reading this data type from the MPU6050.

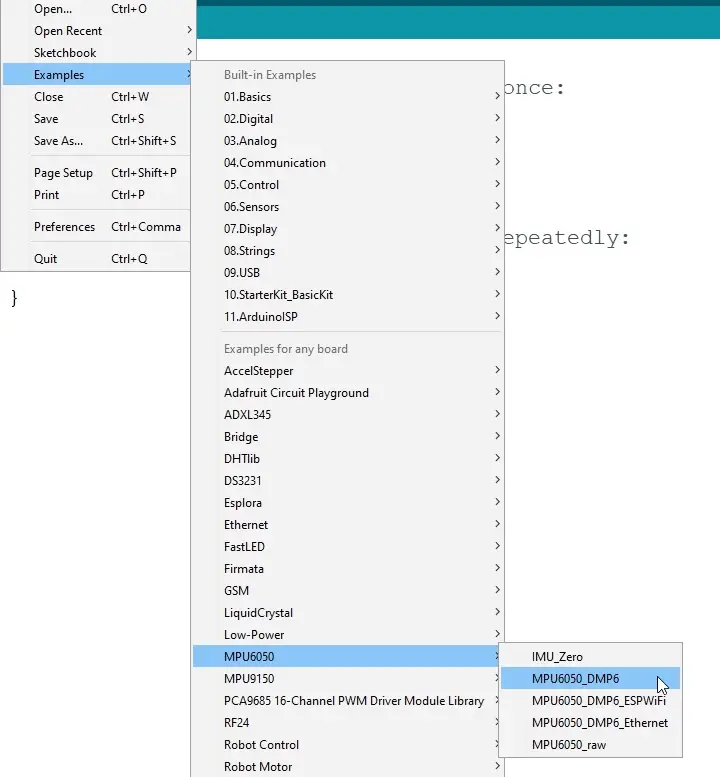

The code is also a bit more complicated so that’s why we are going to use the i2cdevlib library by Jeff Rowberg. This library can be downloaded from GitHub and I will include a link to in on the website article.

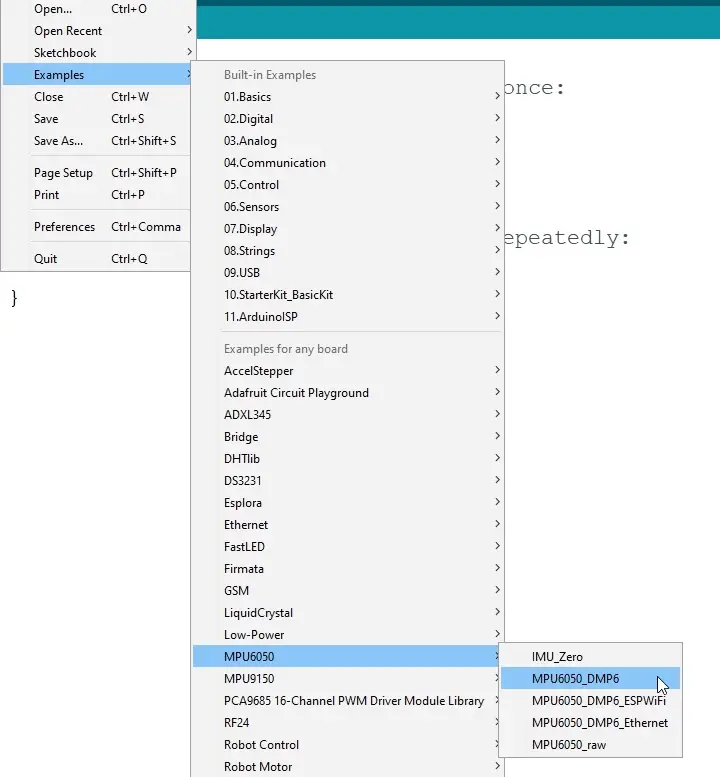

Once we install the library, we can open the MPU6050_DMP6 example from the library. This example is well explained with comments for each line.

Here we can select what kind of output we want, quaternions, Euler angles, yaw, pitch and roll, accelerations value or quaternions for the 3D visualization. This library also includes a Processing sketch for the 3D visualization example. I just modified it to get the box shape as in the previous example. Here’s the 3D visualization Processing code that works with the MPU6050_DPM6 example, for selected “OUTPUT_TEAPOT” output:

/*

Arduino and MPU6050 IMU - 3D Visualization Example

by Dejan, https://howtomechatronics.com

*/

import processing.serial.*;

import java.awt.event.KeyEvent;

import java.io.IOException;

Serial myPort;

String data="";

float roll, pitch,yaw;

void setup() {

size (2560, 1440, P3D);

myPort = new Serial(this, "COM7", 19200); // starts the serial communication

myPort.bufferUntil('\n');

}

void draw() {

translate(width/2, height/2, 0);

background(233);

textSize(22);

text("Roll: " + int(roll) + " Pitch: " + int(pitch), -100, 265);

// Rotate the object

rotateX(radians(-pitch));

rotateZ(radians(roll));

rotateY(radians(yaw));

// 3D 0bject

textSize(30);

fill(0, 76, 153);

box (386, 40, 200); // Draw box

textSize(25);

fill(255, 255, 255);

text("www.HowToMechatronics.com", -183, 10, 101);

//delay(10);

//println("ypr:\t" + angleX + "\t" + angleY); // Print the values to check whether we are getting proper values

}

// Read data from the Serial Port

void serialEvent (Serial myPort) {

// reads the data from the Serial Port up to the character '.' and puts it into the String variable "data".

data = myPort.readStringUntil('\n');

// if you got any bytes other than the linefeed:

if (data != null) {

data = trim(data);

// split the string at "/"

String items[] = split(data, '/');

if (items.length > 1) {

//--- Roll,Pitch in degrees

roll = float(items[0]);

pitch = float(items[1]);

yaw = float(items[2]);

}

}

}

So here using the serialEvent() function we receive the quaternions coming from the Arduino, and in the main draw loop we use them to rotate the 3D object. If we run the sketch, we can see how good quaternions are for rotating objects in three dimensions.

In order not to overload this tutorial, I placed the second example, the DIY Arduino Gimbal or Self-Stabilizing platform, on a separate article.

Feel free to ask any question related to this tutorial in the comments section below and also don’t forget to check my collection of Arduino Projects.

The post Arduino and MPU6050 Accelerometer and Gyroscope Tutorial appeared first on HowToMechatronics.

from HowToMechatronics http://bit.ly/2Kq5xjU

Here is a simple DC motor speed controller circuit that can be configured to control the sweep rate of automobiles’ windscreen wiper. The circuit comprises a timer NE555 (IC1), medium-power driver transistor BD239 (T1), high-power switching transistor BD249 (T2) and a few other discrete components. It is configured for automobile usage with negative terminal of […]

Here is a simple DC motor speed controller circuit that can be configured to control the sweep rate of automobiles’ windscreen wiper. The circuit comprises a timer NE555 (IC1), medium-power driver transistor BD239 (T1), high-power switching transistor BD249 (T2) and a few other discrete components. It is configured for automobile usage with negative terminal of […] This circuit breaker employs a single operational amplifier (op-amp) and yet has a wide range and is user-friendly. A circuit breaker is an electrical switch intended to protect an electrical circuit or device from damage caused by excess current flow or short-circuit. A basic circuit breaker includes a simple fuse and a normal miniature circuit […]

This circuit breaker employs a single operational amplifier (op-amp) and yet has a wide range and is user-friendly. A circuit breaker is an electrical switch intended to protect an electrical circuit or device from damage caused by excess current flow or short-circuit. A basic circuit breaker includes a simple fuse and a normal miniature circuit […] AI is becoming a disruptive force that is redefining the modern industry. This article features some exciting applications of AI, along with a glimpse into the future, illustrating how AI will continue to transform industries and our lives. Sophia, an artificial intelligence (AI) humanoid, was in the news recently for becoming the first robot ever […]

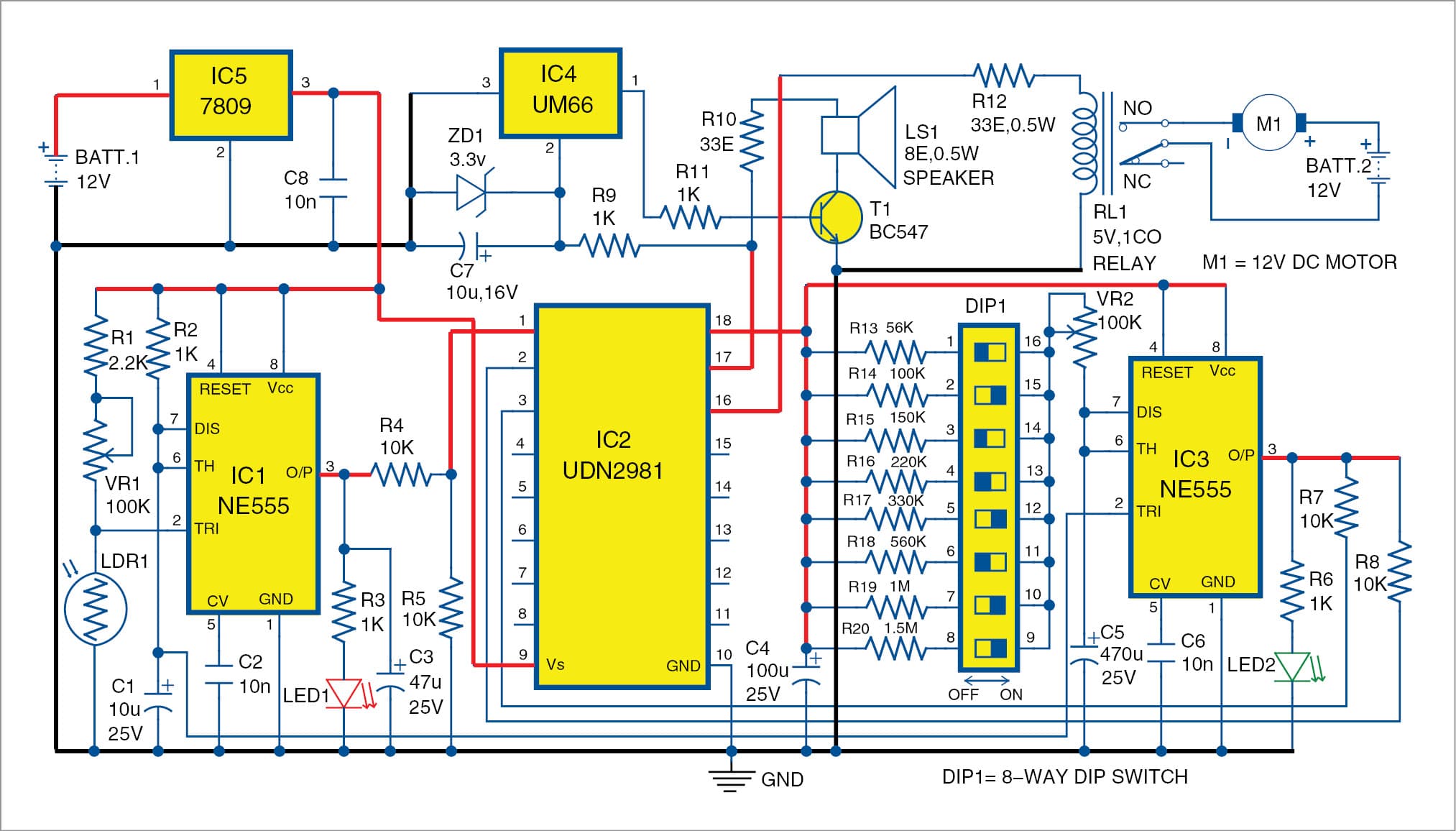

AI is becoming a disruptive force that is redefining the modern industry. This article features some exciting applications of AI, along with a glimpse into the future, illustrating how AI will continue to transform industries and our lives. Sophia, an artificial intelligence (AI) humanoid, was in the news recently for becoming the first robot ever […] Here is a circuit for automatic plants watering, which can be undertaken every morning without any human effort. A sensor is used to detect ambient light and activate a pump motor to start watering the plants in the morning. You can set the watering time duration as per your requirement. The author’s prototype is shown […]

Here is a circuit for automatic plants watering, which can be undertaken every morning without any human effort. A sensor is used to detect ambient light and activate a pump motor to start watering the plants in the morning. You can set the watering time duration as per your requirement. The author’s prototype is shown […] In this article we take a look at the various technology trends and interesting solutions we came across while visiting different parts of the globe throughout the year. Every year brings new opportunities to discover new technological inventions that can deliver real-life improvements. Many of the most-talked-about technologies today were discovered decades ago but have […]

In this article we take a look at the various technology trends and interesting solutions we came across while visiting different parts of the globe throughout the year. Every year brings new opportunities to discover new technological inventions that can deliver real-life improvements. Many of the most-talked-about technologies today were discovered decades ago but have […] Virtual and augmented reality technologies are coming of age and finding many valuable real-world applications. Once upon a time our physical and digital worlds were quite separate, but technological advances are enabling digital worlds to become real enough to merge with the real world. Technologies such as virtual reality (VR) and augmented reality (AR) have […]

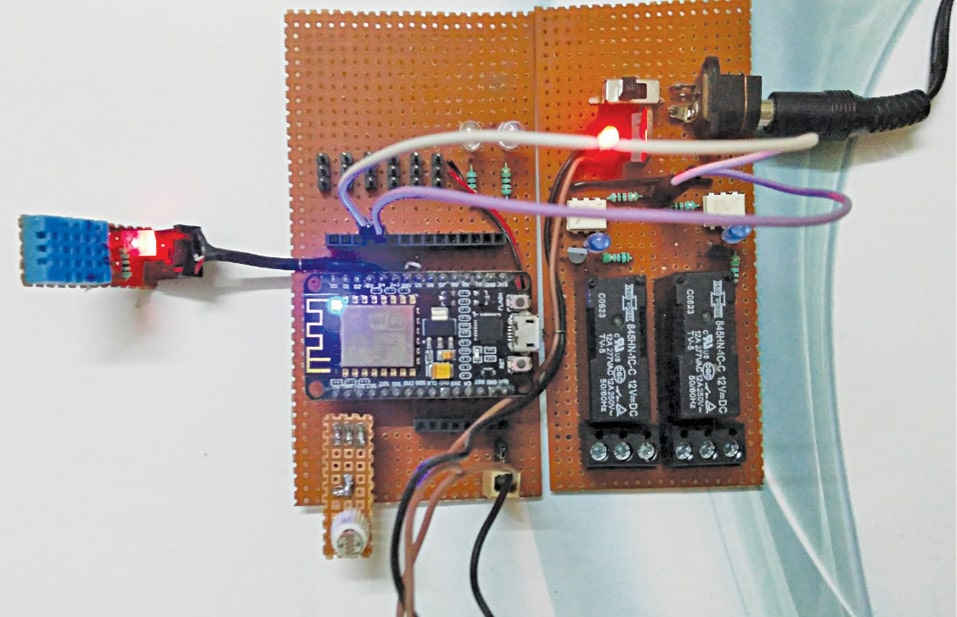

Virtual and augmented reality technologies are coming of age and finding many valuable real-world applications. Once upon a time our physical and digital worlds were quite separate, but technological advances are enabling digital worlds to become real enough to merge with the real world. Technologies such as virtual reality (VR) and augmented reality (AR) have […] This home automation system can measure temperature, relative humidity, light intensity and control two electrical equipment on Cayenne IoT (Internet of Things) platform. The two electrical equipment can be a light bulb and a ceiling fan, or any other electrical devices. The author’s prototype is shown in Fig. 1. Basic IoT components An IoT system […]

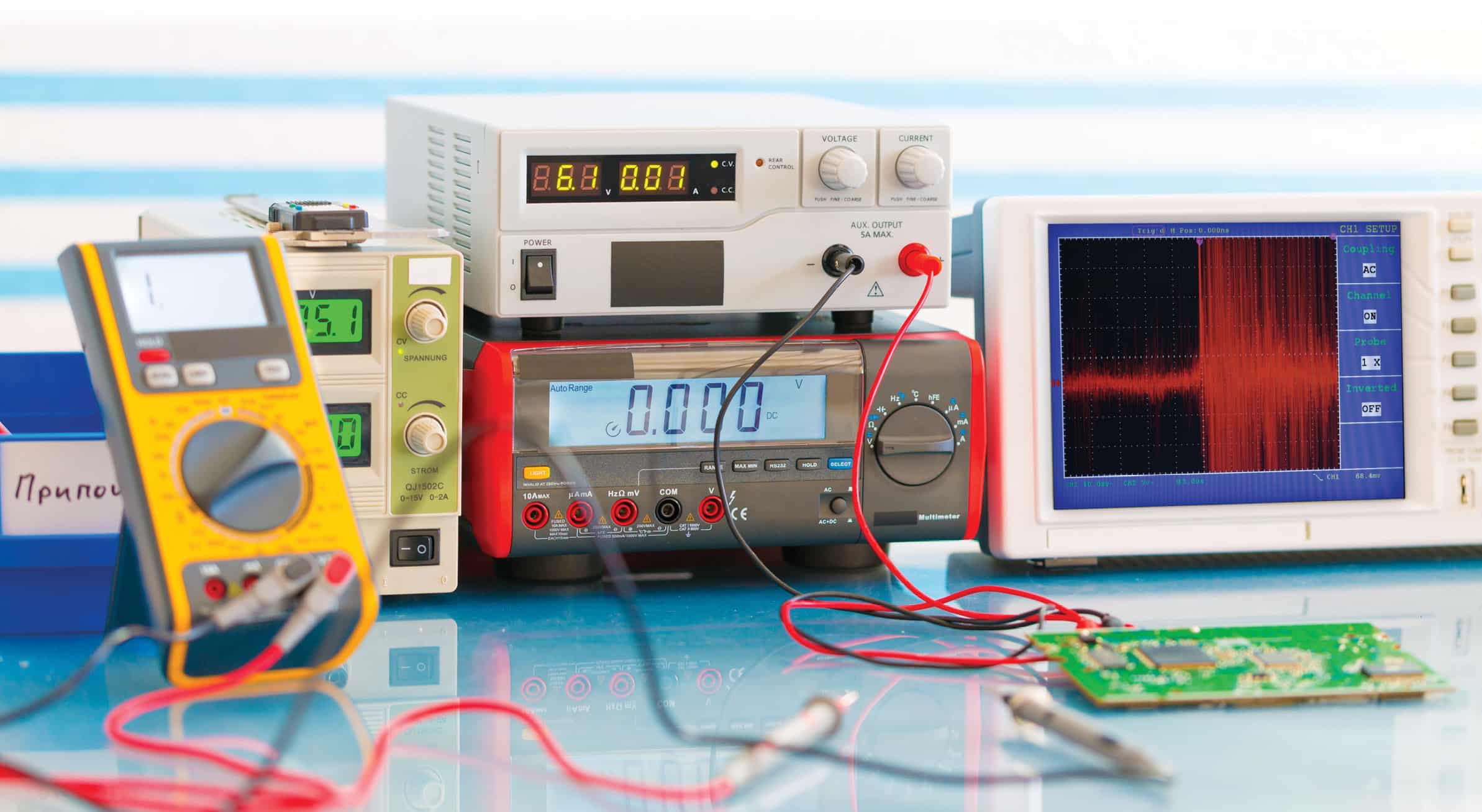

This home automation system can measure temperature, relative humidity, light intensity and control two electrical equipment on Cayenne IoT (Internet of Things) platform. The two electrical equipment can be a light bulb and a ceiling fan, or any other electrical devices. The author’s prototype is shown in Fig. 1. Basic IoT components An IoT system […] A power supply converts AC voltage into regulated DC voltage. Read on to find out how to select the best power supply for an electronic device. A power supply for an electronic equipment is a circuit that converts AC voltage into regulated DC voltage. An electronic device does not normally use electric energy in the […]

A power supply converts AC voltage into regulated DC voltage. Read on to find out how to select the best power supply for an electronic device. A power supply for an electronic equipment is a circuit that converts AC voltage into regulated DC voltage. An electronic device does not normally use electric energy in the […] Dronecode Visit: Click here Full version: Free (BSD licence) Dronecode software development kit (SDK) is an unmanned aerial vehicle (UAV) program development platform created under the open source Dronecode project. It allows users to connect up to 255 PX4-based unmanned aircraft systems (UASes) to provide movement control and fetch telemetry data. It runs on different platforms […]

Dronecode Visit: Click here Full version: Free (BSD licence) Dronecode software development kit (SDK) is an unmanned aerial vehicle (UAV) program development platform created under the open source Dronecode project. It allows users to connect up to 255 PX4-based unmanned aircraft systems (UASes) to provide movement control and fetch telemetry data. It runs on different platforms […] In this video, the presenter is going to show you how he has used Raspberry Pi and a 3.5 inches display unit to create his own mini Pocket Personal computer. It is easy to make and take very less time constructing. Courtesy: The Wrench

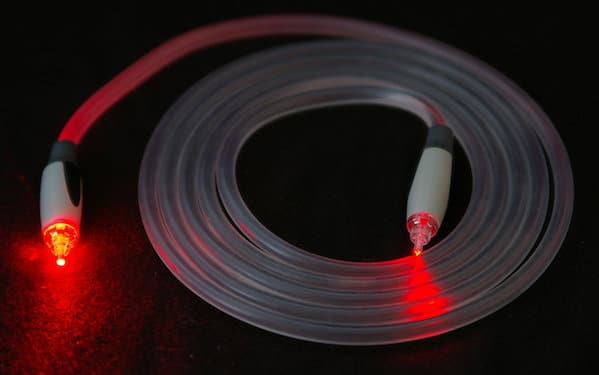

In this video, the presenter is going to show you how he has used Raspberry Pi and a 3.5 inches display unit to create his own mini Pocket Personal computer. It is easy to make and take very less time constructing. Courtesy: The Wrench  In this era of communication and connectivity, optical-fibre sensors find many applications, some of which are discussed in this article. For ages, sensors have been used in hazardous environments. These sensors often contain electronic components. In the past, it was a challenge for engineers to make sensors work at extremely high temperatures, such as in […]

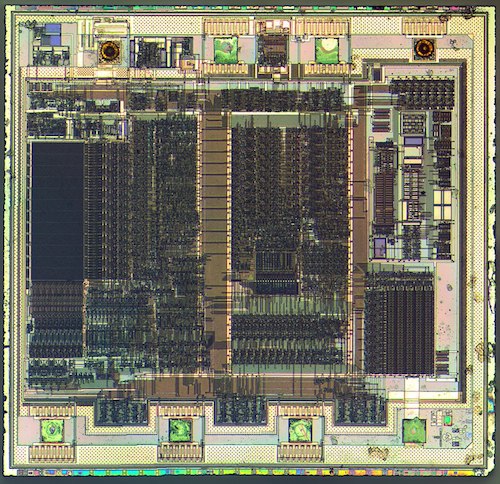

In this era of communication and connectivity, optical-fibre sensors find many applications, some of which are discussed in this article. For ages, sensors have been used in hazardous environments. These sensors often contain electronic components. In the past, it was a challenge for engineers to make sensors work at extremely high temperatures, such as in […] This article highlights common errors in 8-bit instruction sets, and introduces a novel architecture for decimal conversion instructions, especially in 8051, 8086, 8085 and PIC microcontrollers (MCUs). Statistical analysis of different methodologies has revealed that decimal conversion instructions in microprocessors and MCUs do not offer an error-free process. Bugs can be common for the above-mentioned […]

This article highlights common errors in 8-bit instruction sets, and introduces a novel architecture for decimal conversion instructions, especially in 8051, 8086, 8085 and PIC microcontrollers (MCUs). Statistical analysis of different methodologies has revealed that decimal conversion instructions in microprocessors and MCUs do not offer an error-free process. Bugs can be common for the above-mentioned […]

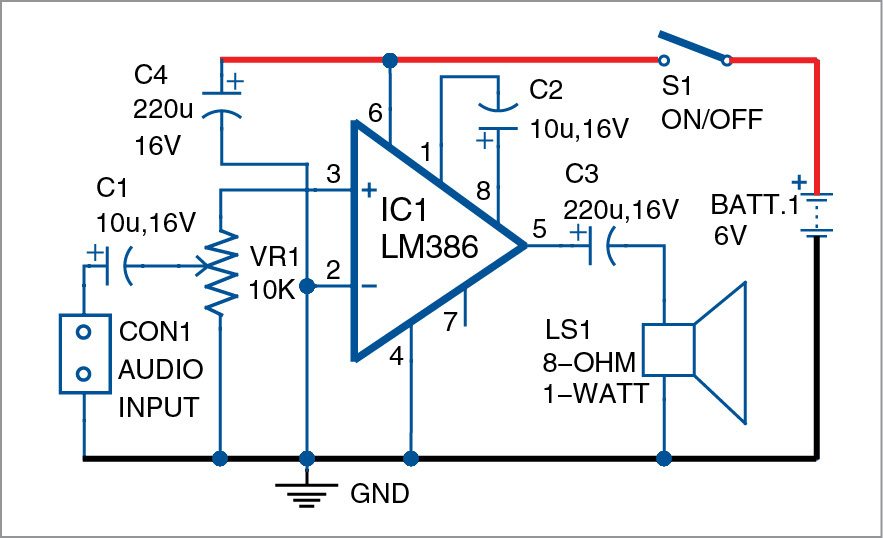

Here is a simple LM386 based audio amplifier circuit with the author’s prototype shown below. LM386 based audio amplifier: circuit and working Circuit diagram of the LM386 based audio amplifier is shown in Fig. 2. It is built around popular amplifier LM386 (IC1), an 8-ohm, one-watt speaker (LS1), four capacitors and a few other components. […]

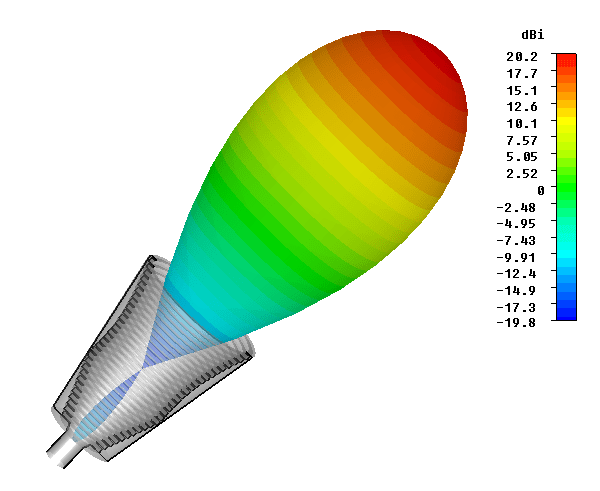

Here is a simple LM386 based audio amplifier circuit with the author’s prototype shown below. LM386 based audio amplifier: circuit and working Circuit diagram of the LM386 based audio amplifier is shown in Fig. 2. It is built around popular amplifier LM386 (IC1), an 8-ohm, one-watt speaker (LS1), four capacitors and a few other components. […] RF antennas or aerials do not radiate equally in all directions. It is found that any realisable RF antenna design will radiate more in some directions than others. The actual pattern is dependent upon the type of antenna design, its size, the environment and a variety of other factors. This directional pattern can be used […]

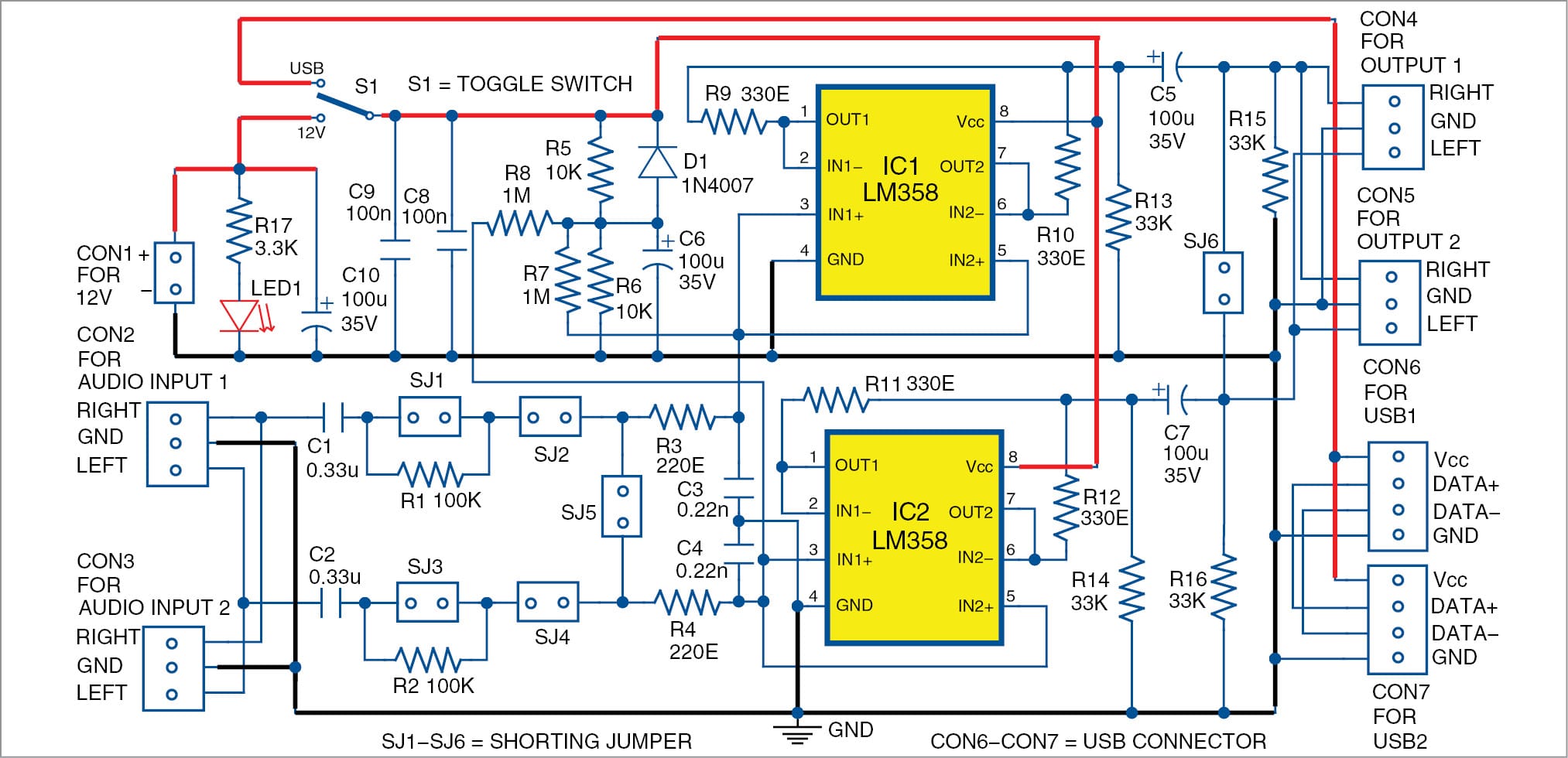

RF antennas or aerials do not radiate equally in all directions. It is found that any realisable RF antenna design will radiate more in some directions than others. The actual pattern is dependent upon the type of antenna design, its size, the environment and a variety of other factors. This directional pattern can be used […] This article presents a simple, low-cost stereo headphones buffer using two LM358 operational amplifiers (op-amps). It is used to connect the headphones to line outputs capable of driving loads up to 600-ohm. The circuit has a high input impedance, low quiescent current and large voltage operating range. Power can be taken either from a USB […]

This article presents a simple, low-cost stereo headphones buffer using two LM358 operational amplifiers (op-amps). It is used to connect the headphones to line outputs capable of driving loads up to 600-ohm. The circuit has a high input impedance, low quiescent current and large voltage operating range. Power can be taken either from a USB […]

Electronic devices, microwaves and other household devices rely on PCB technology to stay in working condition. Lifetime and performance of a PCB board depend on the choice of circuit board material. To select the right circuit board material, it is important to examine the materials available for different board categories. There are different properties and […]

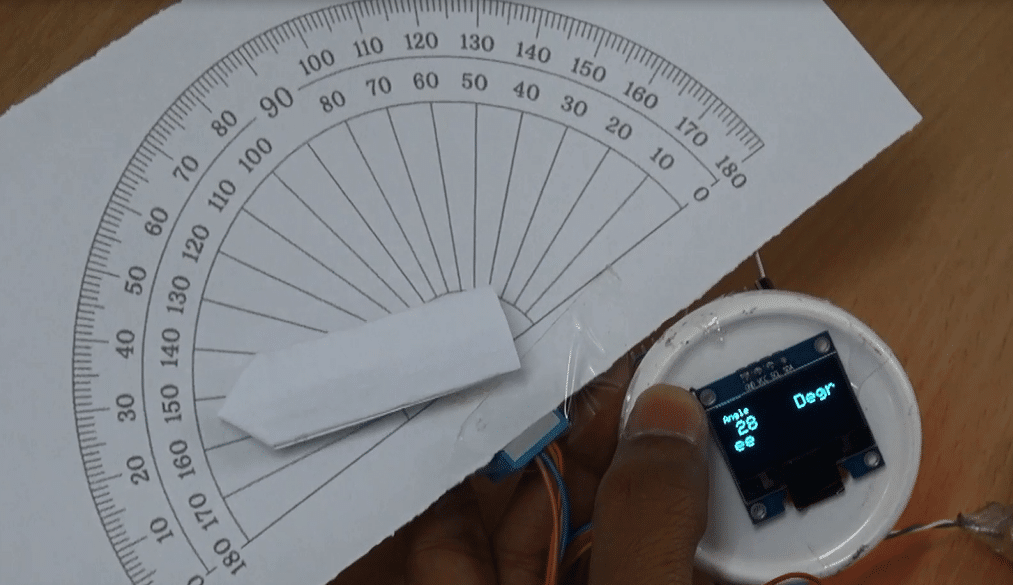

Electronic devices, microwaves and other household devices rely on PCB technology to stay in working condition. Lifetime and performance of a PCB board depend on the choice of circuit board material. To select the right circuit board material, it is important to examine the materials available for different board categories. There are different properties and […] A compass and a protractor are two of the most basic tools used in geometry. For mathematics and engineering students, these tools are a must. But sometimes it is difficult to get accurate angle measurement for certain structures and geometrical shapes using these traditional tools. So, I thought of developing a digital compass to make […]

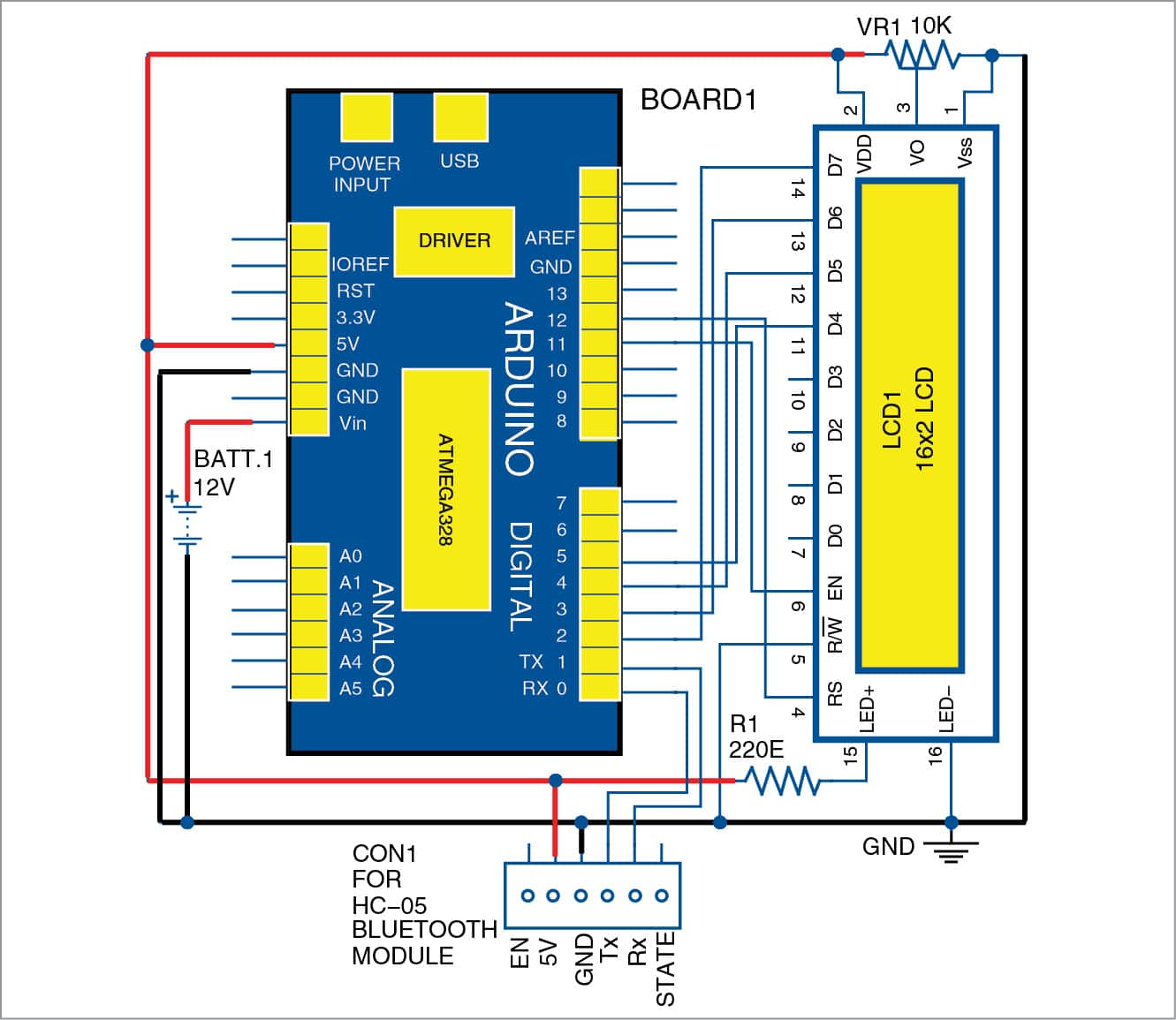

A compass and a protractor are two of the most basic tools used in geometry. For mathematics and engineering students, these tools are a must. But sometimes it is difficult to get accurate angle measurement for certain structures and geometrical shapes using these traditional tools. So, I thought of developing a digital compass to make […] If you are still using the traditional switches, then I’m sorry to say this but they are outdated now. Moreover, these traditional switches have mechanical moving parts which get damaged on continuous use. Nowadays, old switch boards are getting replaced by modern touch switches that not only enhance the look of our homes but are […]

If you are still using the traditional switches, then I’m sorry to say this but they are outdated now. Moreover, these traditional switches have mechanical moving parts which get damaged on continuous use. Nowadays, old switch boards are getting replaced by modern touch switches that not only enhance the look of our homes but are […] Improvements to recommendation systems is a low-hanging fruit that would not only ensure that customers have a high repeat rate but also improve customer experience. Recommendation systems are one of the primary ways in which e-commerce websites tend to generate repeat purchases, that is, getting a purchase from an already registered customer. Repeat purchase is […]

Improvements to recommendation systems is a low-hanging fruit that would not only ensure that customers have a high repeat rate but also improve customer experience. Recommendation systems are one of the primary ways in which e-commerce websites tend to generate repeat purchases, that is, getting a purchase from an already registered customer. Repeat purchase is […] Presented here is a submersible pump starter circuit using electronic overload relay, solid-state relay and adjustable startup delay. A submersible pump is a type of centrifugal pump designed to function with the pump and the motor completely submerged in the water. The motor is sealed in such a way that it prevents any ingress of […]

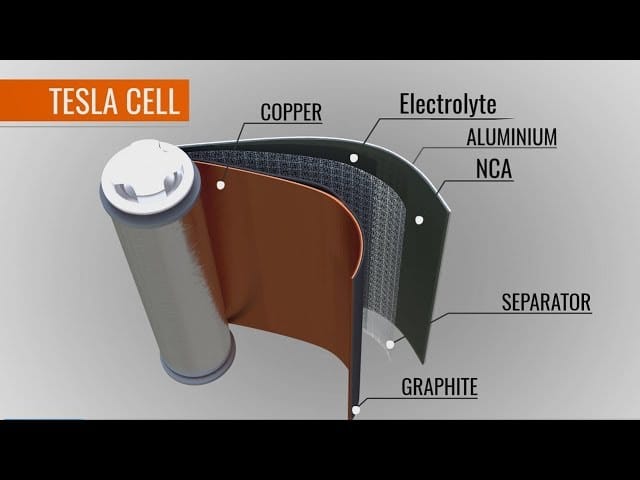

Presented here is a submersible pump starter circuit using electronic overload relay, solid-state relay and adjustable startup delay. A submersible pump is a type of centrifugal pump designed to function with the pump and the motor completely submerged in the water. The motor is sealed in such a way that it prevents any ingress of […] In this video, the presenter is going to share with you the working principle of a Li-ion cell and how it is used in Electric cars. He is going to also explain why Li-ion cell technology is superior to other conventional vehicle technology like combustion engines, induction motors etc. Courtesy: Learn Engineering

In this video, the presenter is going to share with you the working principle of a Li-ion cell and how it is used in Electric cars. He is going to also explain why Li-ion cell technology is superior to other conventional vehicle technology like combustion engines, induction motors etc. Courtesy: Learn Engineering In simple terms, nanotechnology is the part of science that deals with the control of matter with dimensions smaller than 100 nanometres, and can go down to atomic and molecular scales. The study and manipulation of matter, particles and structures on the nanometer scale is referred to as nanoscience. Nanotechnology is the application of nanoscience […]

In simple terms, nanotechnology is the part of science that deals with the control of matter with dimensions smaller than 100 nanometres, and can go down to atomic and molecular scales. The study and manipulation of matter, particles and structures on the nanometer scale is referred to as nanoscience. Nanotechnology is the application of nanoscience […]

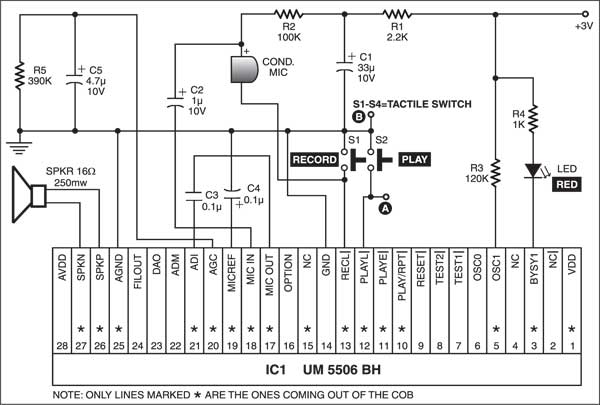

This alarm plays your prerecorded voice message. It is built around the readily available quartz clock. Take the buzzer out of the quartz clock and connect its positive terminal to pin 1 and negative terminal to pin 2 of optocoupler IC MCT2E (IC2). Pin 4 of IC2 is grounded and pin 5 is connected to […]

This alarm plays your prerecorded voice message. It is built around the readily available quartz clock. Take the buzzer out of the quartz clock and connect its positive terminal to pin 1 and negative terminal to pin 2 of optocoupler IC MCT2E (IC2). Pin 4 of IC2 is grounded and pin 5 is connected to […] This simple telephone caller identification display can be very useful for bikers. While riding a bike or any two-wheeler, the cellphone is usually kept in a pocket. When you receive a phone call on your cellphone, you do not know who is calling unless you look at the screen. And sometimes you may not even […]

This simple telephone caller identification display can be very useful for bikers. While riding a bike or any two-wheeler, the cellphone is usually kept in a pocket. When you receive a phone call on your cellphone, you do not know who is calling unless you look at the screen. And sometimes you may not even […]